|

Pulley paradox

discussion.

So why are crowned pulleys necessary for proper tracking of a flat belt? I've seen some internet sites that suggest it has something to do with centrifugal forces. These belts operate at low speeds, and the tracking behavior we wish to explain is easily observed at very low speeds where inertial effects play no role.

One side of the belt on a tapered-diameter pulley has greater tension. Can it be that this gives rise to greater friction, and that friction pulls the belt up the slope? Unfortunately for this hypothesis, the friction acts down the slope on a belt that is moving up the slope.

In the textbook Elements of Mechanism, Third Ed. by Schwamb, Merrill and James (Wiley, 1921), we find a rather insightful answer, at least as applies to a leather or slightly stiff, but still somewhat elastic, belt.

If a belt is led upon a revolving conical pulley, it will tend to lie flat upon the conical surface, and, on account of its lateral stiffness, will assume the position shown in Fig. 52. If the belt travels in the direction of the arrow, the point a will be carried to b, a point nearer the base of the cone than that preposition shown by the dotted lines. Now if a pulley is made up of two equal cones placed base to base, the belt will tend to climb both, and would thus run with its center line on the ridge formed by the union of the two cones... [The amount of crowning varies from about 1/16 inch on a pulley 6 inches wide to about 1/4 inch on a pulley 30 inches wide.]

The belt in contact with the truncated cone lies on the pulley relatively flat and undistorted in shape. But along the dotted line at a the belt moving upward makes first contact with the pulley. Just below a the belt has a slight sidewise bend. But the important thing is that as the belt moves from a to b without slippinng, it moves along the dotted line to a point farther up the incline of the cone, and this process continues until the belt rides onto the apex.

|

Now let's look at the case of a flat belt running over two cylindrical pulleys whose axles are misaligned. Will the belt crawl to the right (where the belt tension will be higher) or to the left (where the tension is lower)? If the belt around the cylindrical pulleys does not slip, there's no geometric reason why the belt would move sidewise on either pulley. A different reason must be sought than the one we found above. Quoting the textbook referenced above:

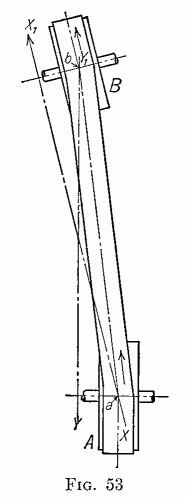

When pulleys are located on shafts which are slightly out of parallel, the belt will generally work toward the edges of the pulleys which are nearer together. The reason for this may be seen from Fig. 53. The pitch line of the belt leaves pulley A at point a. In order to contain this point the center plane of pulley B would have to coincide with XX. Similarly, the belt is delivered from b on the under side of pulley B, into the plane Y1Y. The result of this action is that the belt works toward the left and tends to leave the pulleys.

This passage is a little murky at first reading. The essential difference between the two cases can be seen in the diagrams. In Fig. 1 the belt makes contact with the puley at line a. Note that the upper edge of the pulley (line b) makes an angle with line a. Also, note that line a is perpendicular to the incoming portion of the belt. In Fig 2. the belt makes contact with the puley at line a. Note that the upper edge of the cylindrical pulley (line b) is parallel to line a. Also note that line a is not perpendicular to the incoming portion of the belt. This is the important difference between the two cases. In Fig. 1, each new piece of belt coming onto the pulley is carried, without slipping, to a point higher (to the right in Fig. 1) on the slope. In Fig. 2, each new piece of belt coming onto the pulley is "laid onto" the pulley at a point slightly lower (to the left in Fig. 2) on the slope, and is carried around without slipping.

What I like about this puzzle is that (1) the behavior on the crowned pulley is counter-intuitive; (2) most of the initial hypotheses you make will turn out to be wrong; and (3) some explanations of the crowned pulley seem so "right"—until you apply the same reasoning to the parallel shaft problem, then it's "back to the drawing-board". I like puzzles that have several levels of apparent paradox and counter-intuitive features. They teach us not to trust our intuition, which is a good thing. Intuition can sometimes be a part of the problem solving process, but at some point, it must give way to "sweating the details" and being ruthlessly critical of "plausible-sounding" answers.

|

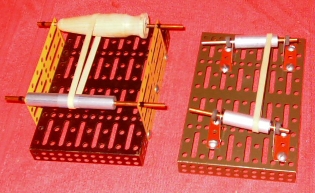

Fig. 3 shows rubber-band models made with steel construction set parts and wooden pulleys. The model on the left has a wooden file handle as a pulley. This serves to illustrate how the rubber band will migrate along the wooden pulley from the narrowest part at the left, to the its largest diameter. The file handle has both convex and concave profiles. Placed in the concave part, the rubber band will quickly rise up the slope and will stabilize at the largest radius, even if that is the very narrow portion near the right end. In the misaligned cylindrical pulley model, on the right, the rubber band moves to the left side, where the pulleys are closer together, contrary to most people's expectations. It's better to use wooden dowels, or cover the metal cylinder surfaces with something like cloth tape to prevent belt slippage.

![]() Input and suggestions are welcome at the address shown to the right. When

commenting on a specific document, please reference it by

name or content.

Input and suggestions are welcome at the address shown to the right. When

commenting on a specific document, please reference it by

name or content.

Return to Physics documents.

Return to Crowned pulley problem.

Return to Physics Problems to Challenge Understanding.

Return to Donald Simanek's front page.