Pulley paradox.

|

Flat belts still find applications in machinery. Conveyor belts are a common example. During the 19th and early 20th century flat leather belts were often found driving machinery in factories, and for conveying power from engines to farm machinery.

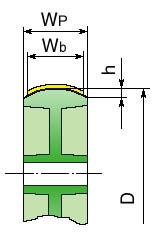

Such belts running over cylindrical pulleys quickly wander off the pulleys. To prevent this, at least one pulley is "crowned", machined to a slightly "spindle" shaped profile. The figure shows two kinds of crowned pulleys.

|

When the flat belt on such a pulley is off-center and the pulley rotating, the belt quickly moves up to the largest radius at the top of the crown and stays there. The crown is important to keep the belt "tracking" stable, preventing the belt from "walking off" the edge of the pulley. A crowned pulley eliminates the need for pulley flanges and belt guide rollers. This seems counter-intuitive at first. So your job is to figure out why this happens, and explain it fully enough to account for the observed behavior.

It seems plausible that the belt riding on the crown should be stable, and a look at this picture helps. However, it's less easy to see why a belt on a tapered pulley will always "climb the hill" to find the portion of the pulley with greatest radius.

Of course tension in the belt has something to do with it, as does friction. Without friction the belt wouldn't behave this way, but then without friction, any pulley would be useless. More explanation is required than simply to say "It's because of ...."

|

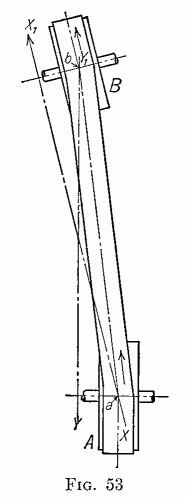

To test your answer, see what it would predict for the case of a flat belt running over two cylindrical pulleys whose axles are misaligned. Will the belt crawl to the right (where the belt tension will be higher) or to the left (where the tension is lower)? If you said the belt will move to the right, just as the belt on the crowned pulley moves to a position of higher tension, you'd better rethink your answer, for this belt moves to the left, to lower tension.

What I like about this puzzle is that (1) the behavior on the crowned pulley is counter-intuitive; (2) most of the initial hypotheses you make will turn out to be wrong; and (3) some explanations of the crowned pulley seem so "right"—until you apply the same reasoning to the parallel shaft problem, then it's "back to the drawing-board". I like puzzles that have several levels of apparent paradox and counter-intuitive features. They teach us not to trust our intuition, which is a good thing. Intuition can sometimes be a part of the problem solving process, but at some point, it must give way to "sweating the details" and being ruthlessly critical of "plausible-sounding" answers.

On crowning.

When a flat belt runs over two pulleys, only one of them needs to be crowned to achieve lateral stability. The amount of curvature required in actual machinery is small. [The usual figure for the amount of crowning is 1/8 inch per foot of pulley width. Thus, the difference in maximum and minimum radii of a crowned 6-inch wide pulley would be 1/16 inch.] The method works for belts of leather or rubberized fabric that have some elasticity. You can demonstrate the assertions above by making a small model with axles and rubber band belts. A wooden turning, or a tapered tool handle works well for one pulley.

The driving pulley is the one usually crowned. Crowning both pulleys can cause instabilities in tracking.

The large diameter idler wheel of a shop band saw has a rubber crowned tire. The metal blade is made to run true, on top of the crown, by adjusting the axle tilt of that wheel. This metal belt is not flexible, and the principle at work here is a bit different than for a leather or rubber belt, though the result seems superficially to be the same. Consider this a separate puzzle.

Though you will find much descriptive material on crowned pulleys on the internet, I have not yet found a good explanation of the physics of how it works. Several sites identify the factors that are important, and come very close to an explanation. Old textbooks on mechanics from a century ago sometimes have good treatments of this. Only one book in my personal library even mentions pulley crowning, and it was written in 1885. I will post my explanation here, after readers have had a chance to puzzle it out for themselves. Correspondence is invited, and if a reader supplies a really good explanation, I won't have to write up mine.

One wonders when the advantages of pulley crowning were discovered, and how it came about. Hans-Peter Gramatke informs me that:

Flat leather belts came up with the industrial revolution. I do not know of a machine which has crowned pulleys before 1840, but I do not have a better estimate. As I have an image of a revolver turning-machine from 1845, clearly showing crowmed pulleys, I assume this construction feature was already well-known at that time. At least I can say that ropes and pulleys with rims were used until the 1880s—in parallel with flat belts.

![]() Input and suggestions are welcome at the address shown to the right. When

commenting on a specific document, please reference it by

name or content.

Input and suggestions are welcome at the address shown to the right. When

commenting on a specific document, please reference it by

name or content.

Return to Physics documents.

Return to Physics Problems to Challenge Understanding.

Return to Donald Simanek's front page.